Sheet Metal Cloud Software Upgraded to Include Assembly Analysis and CAD Plug-In

Optimate, the TRUMPF spin-off, has introduced two extensive upgrades to its cloud-based software solution for analyzing and optimizing sheet metal parts.

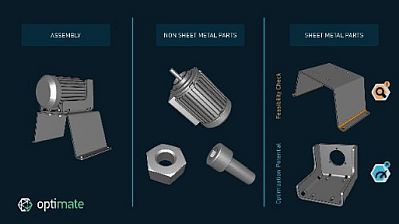

Digitalization in sheet metal processing: Assemblies with up to 25 individual parts can now be checked for feasibility and optimization potential in an automated and AI-based way in the App platform.

In response to increasing user demand, assemblies with up to 25 individual parts can now also be analyzed. Moreover, a new CAD plug-in for SolidWorks makes design optimization even more user-friendly.

Optimate's digital service includes two main functions: Feasibility Analysis and Part Optimization. Both have been given a user-friendly upgrade with the new features.

Sheet metal processing companies in particular will be pleased with the option to check assemblies for feasibility. "In our App, job shoppers can identify defective parts in advance and adapt them as required before they reach the bending machine," explains CEO Jonas Steiling. "We have now extended this analysis to include assemblies."

Analyzing and Optimizing Assemblies

In addition to the analysis of single parts, assemblies with up to 25 individual parts can now also be checked for feasibility and optimization potential.

Test customers wanted: The TRUMPF start-up is looking for more test users from the sheet metal processing industry for its new SolidWorks CAD plug-in.

To this end, the assembly uploaded to the App is being dissolved into its individual parts and examined under a digital microscope. "For single sheet metal parts, our service already works entirely automatically," reports Sales Director Sebastian Beger. "For the comprehensive analysis and optimization of assemblies, it is currently still a hybrid process: Following the initial analysis with our tool, we take another look at the assemblies ourselves and offer personal consulting. In the future, we will fully automate the entire process."

The AI-based solution's database will help ensure that the new assembly analysis function will also be available in a fully automated form in the long term.

Available Now: CAD Plug-In for SolidWorks and Adaptation of Individual Machine Data

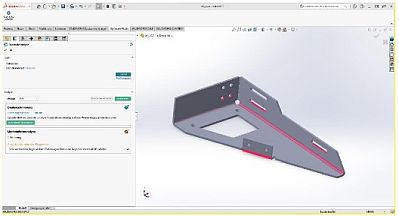

Optimate also recently began offering a beta version of its new SolidWorks CAD plug-in for trial customers.

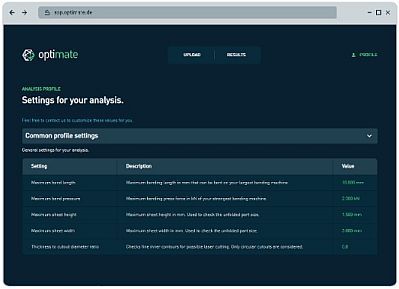

Personal analysis profile in the Optimate App: The maximum bend length, maximum bend pressure, existing tool pairings and individual minimum flange lengths are used for the feasibility analysis.

With the plug-in, designers benefit from an improved workflow because they can test and optimize their parts for feasibility directly in the system without having to export the CAD data and upload it to the App. Since the user best understands the application case, he can now view the design proposals directly in the CAD system and check them for suitability. The final decision to adapt or optimize a part is up to the designer.

"We are currently looking for more test customers for our SolidWorks CAD plug-in," says Jonas Steiling. There are also plans to continuously advance the CAD plug-in and integrate it into CAD programs from other providers.

Also new is the full customization of all analysis-relevant settings for the part analysis. Machine data can be customized and viewed on the user profile in the App. For example, the maximum bend length, maximum bend pressure, existing tool pairings or individual minimum flange lengths are stored and used for feasibility analysis.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::